- About Us

- Our Products

- Industries

- Business

- Our Services

- Steel News

- Contact Us

Tinplate is a lightweight, low-carbon steel sheet or strip coated with pure tin on both surfaces. It offers excellent corrosion resistance, soldering capability, and an attractive appearance. The steel composition used is carefully controlled to ensure quality. Tinplate is available in different forms and thicknesses, with varying tin coatings and surface finishes. It is versatile and can be used in various industrial and packaging applications.

Recyclable

Recyclable

Degradable

Degradable

Non Reactive Tin

Non Reactive Tin

Excellent Printing

Excellent Printing

Food Packaging

Food Packaging

1.0/1.0, 2.0/2.0, 2.8/2.8, 5.6/5.6 (g/m²)

1.0/2.8, 2.8/4.0, 2.8/5.6, 2.0/5.6 (g/m²)

T1, T2, T3, T4, T5

DR7, DR8, DR9

Bright, Stone, Silver, Matt

T1, T2, T3, T4, T5

Galvanized Steel Strips and Sheets (Plain & Corrugated)- Specification (Seventh Revision)

Steel Drums (galvanized And Ungalvanized)

Steel Drums (galvanized And Ungalvanized)

Steel Drums (galvanized And Ungalvanized)

Galvanized Structural Steel — Specification

Galvanized Structural Steel — Specification

Galvanized Structural Steel — Specification

Electrogalvanized Hot Rolled and Cold Reduced Carbon Steel Sheets and Strips — Specification

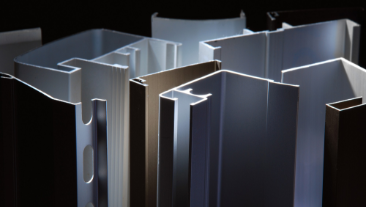

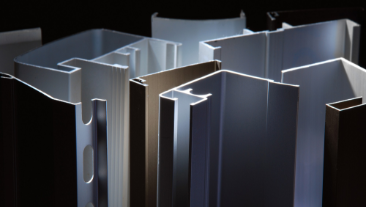

Electrolytic tin plate creates furniture profiles with uniform dimensions and a sleek finish, improving structural integrity, quality, and design versatility.

Electrolytic tin plate is the preferred material for chemical packaging cans due to its corrosion-resistant properties, which ensure the safe containment of diverse chemical substances.

Electrolytic tin plates are commonly used for producing durable paint containers with a smooth surface and optimal formability for easy handling and storage.

Electrolytic tinplate is a robust material used to make sturdy metal containers for various industries. These containers are precise in size and strength, ideal for safely transporting multiple materials from food to industrial supplies.

Electrolytic tin plates produce cost-effective and malleable imitation jewellery with intricate designs and a smooth surface finish, meeting fashion industry demands.

Electrolytic tin plate creates furniture profiles with uniform dimensions and a sleek finish, improving structural integrity, quality, and design versatility.

Electrolytic tin plate is the preferred material for chemical packaging cans due to its corrosion-resistant properties, which ensure the safe containment of diverse chemical substances.

Electrolytic tin plates are commonly used for producing durable paint containers with a smooth surface and optimal formability for easy handling and storage.

Electrolytic tinplate is a robust material used to make sturdy metal containers for various industries. These containers are precise in size and strength, ideal for safely transporting multiple materials from food to industrial supplies.

Electrolytic tin plates produce cost-effective and malleable imitation jewellery with intricate designs and a smooth surface finish, meeting fashion industry demands.

contact us

contact us

And because your company is unique, you will need an extensible identity solution.