- About Us

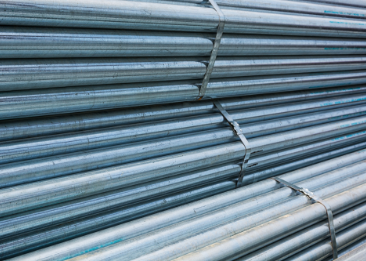

- Our Products

- Industries

- Business

- Our Services

- Steel News

- Contact Us

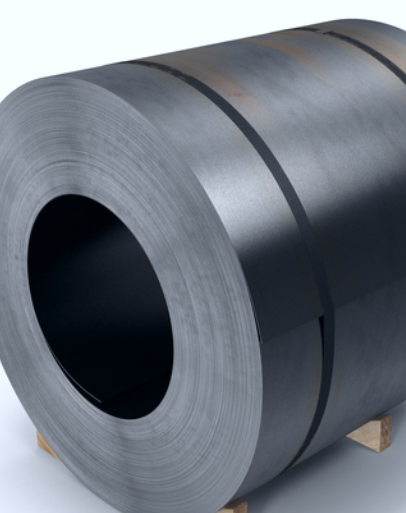

Cold-rolled steel is produced by passing hot rolled steel through rollers below its recrystallization temperature. This process is done to enhance its mechanical and dimensional properties. The metal is compressed and squeezed, resulting in increased yield strength and hardness. Cold rolling of metal strips is a specialized segment in the metalworking industry. Cold-rolled steel has several advantages, such as:

Higher Precision

Greater strength

Better surface finishes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Low carbon high strength cold rolled steel sheets and coils for cold forming

Cold Rolled Brass Sheet, Strip And Foil

Cold rolled non-oriented electrical steel sheet and strip - Fully processed type

Cold-reduced and hot-rolled carbon steel sheet for porcelain enameling

Low carbon high strength cold rolled steel sheets and coils for cold forming

Cold Rolled Non-Oriented Electrical Steel Sheet and Strip - Semi-Processed Type

Cold-Rolled Steel Sheet Products - Dimensional and Shape Tolerances ( First Revision )

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Cold-rolled Carbon Steel Strips/Coils for Manufacture of Welded Tubes

Low carbon high strength cold rolled steel sheets and coils for cold forming

| S.No | JSW GRADES | TATA GRADES | SAIL GRADES | AMNS GRADE | BIS GRADES |

|---|---|---|---|---|---|

| 01 | CQ | CQ | CR1 | CR1 | CR1 |

| 02 | DQ | DQ | CR2 | CR2 | CR2 |

| 03 | DDQ | DDQ | CR3 | CR3 | CR3 |

| 04 | EDDQ | EDDQ | CR4 | CR4 | CR4 |

| 05 | IF | IF | CR5 | CR5 | CR5 |

Steel and tin packaging are durable, recyclable, and corrosion-resistant, which makes them an ideal sustainable packaging solution for protecting goods and preserving product quality.

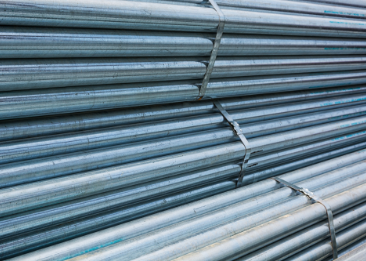

Cold-rolled sheets are vital for coated sheets. The process smoothens the metal for coating. Adding zinc or aluminium boosts its durability and corrosion resistance. Coated sheets are used in construction, automotive, and appliance manufacturing, offering improved properties and resilience.

Cold-rolled sheets are vital in building railway coaches. They provide strength and precision, ensuring durability and safety. They create a reliable foundation for the robust structures needed in railway transportation.

Cold-rolled sheets are crucial for crafting electrical panel enclosures and structural elements. Their inherent properties of precise dimensions and smooth surfaces ensure optimal performance and longevity.

Cold-rolled sheets are crucial for constructing various parts in the automotive industry. The process enhances mechanical properties, ensuring the strength and longevity of components, resulting in reliable and safe performance on the road.

Steel and tin packaging are durable, recyclable, and corrosion-resistant, which makes them an ideal sustainable packaging solution for protecting goods and preserving product quality.

Cold-rolled sheets are vital for coated sheets. The process smoothens the metal for coating. Adding zinc or aluminium boosts its durability and corrosion resistance. Coated sheets are used in construction, automotive, and appliance manufacturing, offering improved properties and resilience.

Cold-rolled sheets are vital in building railway coaches. They provide strength and precision, ensuring durability and safety. They create a reliable foundation for the robust structures needed in railway transportation.

Cold-rolled sheets are crucial for crafting electrical panel enclosures and structural elements. Their inherent properties of precise dimensions and smooth surfaces ensure optimal performance and longevity.

Cold-rolled sheets are crucial for constructing various parts in the automotive industry. The process enhances mechanical properties, ensuring the strength and longevity of components, resulting in reliable and safe performance on the road..

contact us

contact us

And because your company is unique, you will need an extensible identity solution.