- About Us

- Our Products

- Industries

- Business

- Our Services

- Steel News

- Contact Us

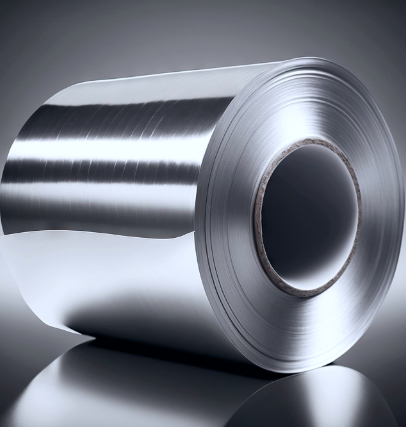

Galvanization is a manufacturing process that involves applying a layer of zinc coating to steel to prevent rust. This protective layer of zinc acts as a barrier against various corrosive elements, ultimately enhancing the quality and longevity of the steel product. Galvanized sheet metal is a highly favoured type of steel due to its increased strength, prolonged durability, and improved formability. The fundamental principle behind galvanization is to create a permanent bond between the steel and zinc, resulting in a more rust-resistant base metal.

Galvanized Steel Strips and Sheets (Plain & Corrugated)- Specification (Seventh Revision)

Steel Drums (galvanized And Ungalvanized)

Galvanized Structural Steel — Specification

Electrogalvanized Hot Rolled and Cold Reduced Carbon Steel Sheets and Strips — Specification

Hot-dip galvanization is the process of coating steel with zinc by dipping it into a bath of molten zinc. The steel is cleaned and fluxed before immersion to ensure a strong bond forms between the zinc and the steel. Once removed from the bath, the zinc reacts with oxygen and carbon dioxide to create a robust protective layer.

This alternative process for galvanization avoids a molten zinc bath and instead uses an electric current and an electrolyte solution to deposit zinc ions onto the metal substrate. This results in a consistently precise and uniformly thick zinc coating, making it a preferred choice for applications where accurate coating thickness is crucial.

| S.No | JSW GRADES | TATA GRADES | SAIL GRADES | AMNS GRADE | BIS GRADES |

|---|---|---|---|---|---|

| 01 | CQ | CQ | CR1 | CR1 | CR1 |

| 02 | DQ | DQ | CR2 | CR2 | CR2 |

| 03 | DDQ | DDQ | CR3 | CR3 | CR3 |

| 04 | EDDQ | EDDQ | CR4 | CR4 | CR4 |

| 05 | IF | IF | CR5 | CR5 | CR5 |

Reliable Coating

Reliable Coating

Durable

Durable

Cost Effective

Cost Effective

Complete Coverage

Complete Coverage

Fast Turnaround

Fast Turnaround

Thanks to its superior finish and mechanical properties, galvanized steel is vital in making solid and durable automotive body parts and components.

Galvanized steel is commonly used in construction for roofing, cladding, and framing due to its accuracy, smooth surface, and strength.

Galvanized steel is vital in telecommunications for enclosures, cabinets, and components. Its precise finish and formability meet customization needs and industry standards.

Crafting reliable and visually appealing electric equipment that adheres to stringent industry standards requires galvanized steel due to its protective zinc coating and malleability. Galvanized steel is essential for reliable electric equipment that meets industry standards.

Galvanized steel is the preferred material for fabricating outer panels, doors, and structural components of white goods. Galvanised steel has durability, aesthetic appeal, refined surface finish, and enhanced strength.

Thanks to its superior finish and mechanical properties, galvanized steel is vital in making solid and durable automotive body parts and components.

Galvanized steel is commonly used in construction for roofing, cladding, and framing due to its accuracy, smooth surface, and strength.

Galvanized steel is vital in telecommunications for enclosures, cabinets, and components. Its precise finish and formability meet customization needs and industry standards.

Crafting reliable and visually appealing electric equipment that adheres to stringent industry standards requires galvanized steel due to its protective zinc coating and malleability. Galvanized steel is essential for reliable electric equipment that meets industry standards.

Galvanized steel is the preferred material for fabricating outer panels, doors, and structural components of white goods. Galvanised steel has durability, aesthetic appeal, refined surface finish, and enhanced strength.

contact us

contact us

And because your company is unique, you will need an extensible identity solution.