- About Us

- Our Products

- Industries

- Business

- Our Services

- Steel News

- Contact Us

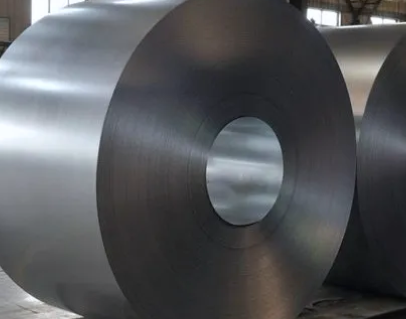

Tin Mill Black Plate (TMBP) steel is made from Hot Rolled Coils that are pickled, cold-rolled, and processed for formability, surface texture, and flatness. It's widely used in general line cans, automotive, and construction components, as well as in Tinplate and tin-free steel due to its uniform thickness and excellent flatness.

1.0/1.0, 2.0/2.0, 2.8/2.8, 5.6/5.6 (g/m²)

1.0/2.8, 2.8/4.0, 2.8/5.6, 2.0/5.6 (g/m²)

T1, T2, T3, T4, T5

DR7, DR8, DR9

Bright, Stone, Silver, Matt

T1, T2, T3, T4, T5

Electrogalvanized Hot Rolled and Cold Reduced Carbon Steel Sheets and Strips — Specification

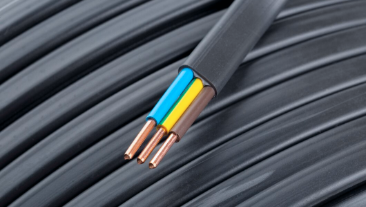

Tin Mill Black Plate provides robust cable armour, protecting electrical and communication cables from external elements and mechanical stress.

Tin Mill Black Plate creates corrosion-resistant deck plates for ships and offshore structures. Its dimensional accuracy and smooth surface finish enhance structural integrity.

Tin Mill Black Plate is essential in producing metal lath, a versatile construction material for wall and ceiling applications. Its formability and consistent surface finish make it suitable for diverse construction projects.

Tin Mill Black Plate is commonly used in construction for roofing, framing, and cladding due to its strength and dimensional accuracy, ensuring the longevity and stability of structures.

Tin Mill Black Plate produces secure and dependable packaging for various consumer goods, including food, beverages, and other commodities.

Tin-free steel is used for bottle caps, providing precise dimensions, strength, and tamper resistance. The resulting metal caps are durable and malleable, suitable for various containers. Its consistent surface finish and accuracy make it ideal for diverse packaging applications.

Tin-free steel is ideal for chemical packaging. It is corrosion-resistant and ensures product integrity during storage and transportation.

Tin-free steel is used in electronics to manufacture high-performance PCBs with precise dimensions and smooth surfaces for optimal device functionality.

Tin-free steel is commonly used to make paint containers due to its formability and smooth surface finish, which ensures safe storage and easy use of paint products.

Photographic films are stored in tin-free steel cases due to their consistent dimensions and strength, which protect and preserve sensitive materials and ensure their longevity.

contact us

contact us

And because your company is unique, you will need an extensible identity solution.